Description

How a Titanium Ring Is Made

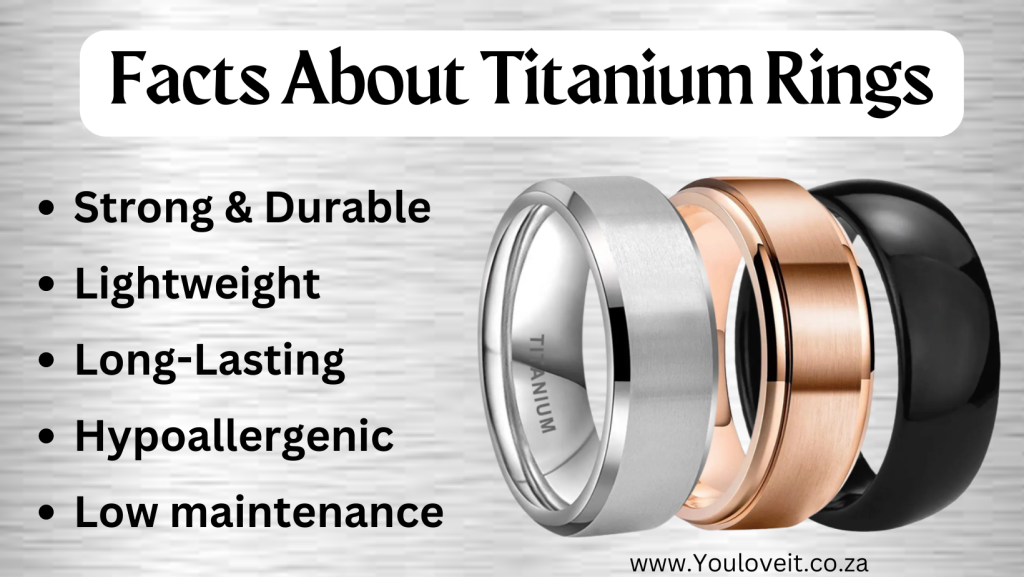

- Material Selection: Titanium, a lightweight yet durable metal, is chosen for its strength, corrosion resistance, and hypoallergenic properties.

- Shaping: A solid titanium billet or rod is cut into the rough size of the desired ring. It is then machined using a lathe or CNC equipment to achieve a smooth, circular shape.

- Sizing: The ring is drilled and turned to achieve the precise inner diameter and width for the intended size.

- Polishing and Finishing: The ring is sanded and polished to create a smooth or textured finish. Designs such as grooves, bevels, or inlays are added as required.

- Customizations: Options like engraving, inlaid materials (e.g., wood, carbon fiber, or gemstones), or texturing are applied for personalization.

Gold Plating on Titanium Rings

- Firstly, Surface Preparation: The titanium ring’s surface is cleaned and smoothed to remove impurities and ensure proper adhesion of the plating.

- Base Layer: A thin layer of an intermediary metal like palladium or nickel may be applied to help the gold bond effectively to the titanium.

- Electroplating Process: The ring is submerged in a gold solution, and an electric current is applied. This causes gold ions to deposit evenly onto the surface of the ring.

- Finishing Touches: After plating, the ring is polished and inspected to ensure even coverage and a flawless finish.

Lastly, Laudium is a vibrant suburb in the western part of Centurion, located near Pretoria, South Africa. Known for its rich cultural heritage, it features residential areas, schools, and local businesses. However, Centurion, a thriving city, lies between Pretoria and Johannesburg, offering modern amenities, shopping hubs, and excellent connectivity via major highways.